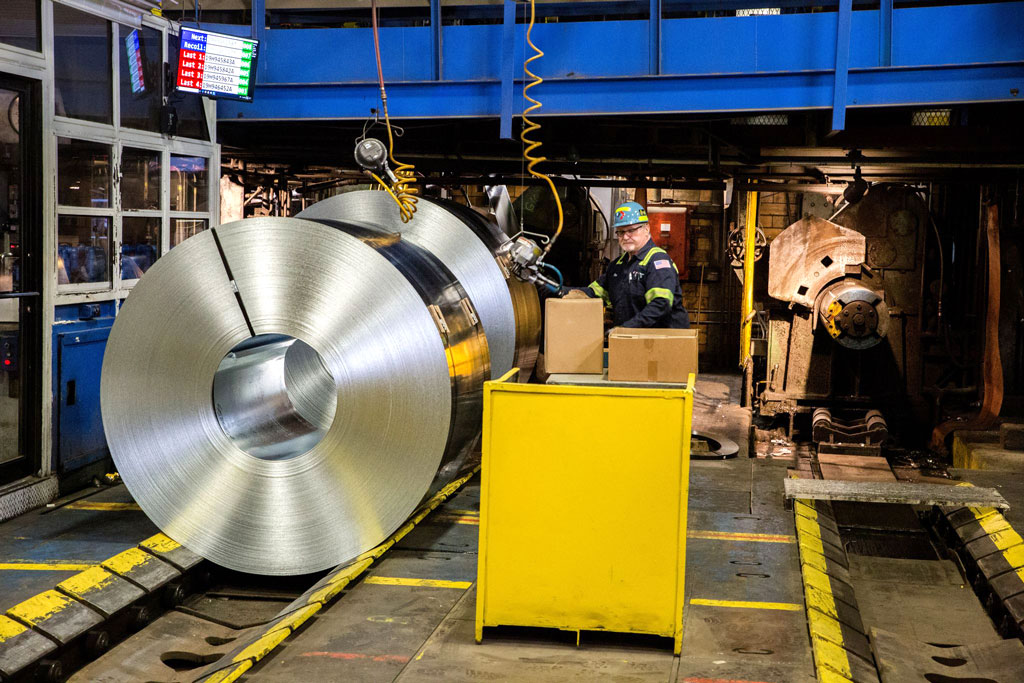

Steel Dynamics Inc. in Sinton is partnering with Nextracker and JM Steel to dedicate a production line designed to meet a demand increase in utility-scale solar power projects. Courtesy photo

Nextracker and JM Steel partner in production with Steel Dynamics

Rising demand for large-scale solar farms in Texas and the southern United States has created a need for a dedicated manufacturing line at the Steel Dynamics Inc. facility in Sinton.

Nextracker, the global market leader in utility-scale solar trackers, and JM Steel, a steel-processing technology provider, announced the opening of the line on Wednesday, April 20. The expanded capacity will enable quick-ship response times to customers in three major regions via the Port of Corpus Christi. Also, costs are reduced by integrating key manufacturing activities on a single campus.

“Customers want protection from steel and logistics cost volatility and logistics delays associated with shipping, containers, and ports,” said Dan Shugar, founder and CEO of Nextracker, in a statement. “We are migrating to domestic production to stabilize pricing and achieve superior on-time delivery for our customers.”

The steel production process uses "Next Generation" electric-arc-furnace technology. Recycled or scrap steel is used as the raw material for a lower carbon footprint.

“U.S. steel manufacturers like Steel Dynamics Incorporated have a much cleaner, lower carbon-generating process than most overseas manufacturers,” Shugar said.

Texas became the top-ranked state for solar capacity additions when 6,060 megawatts of solar power were added in 2021, according to the Solar Energy Industries Association. California was knocked to second place.

SDI Sinton is the newest steel mill in America and celebrated a ribbon-cutting on Feb. 9.